Vacuum Pump Repair and Rebuild

While working at the VCU Innovation Machine Shop as a Shop Foreman during my freshman year at college, I was tasked with the project of getting this vacuum pump working again. This Edwards RV12 high-power rotary vane vacuum pump, costing over $3400 when new, was ran out of oil. Similar to a car engine, there are many moving parts that make metal-on-metal contact, so running low on oil could cause many problems in the pump mechanism.

Pictures taken throughout the repair process.

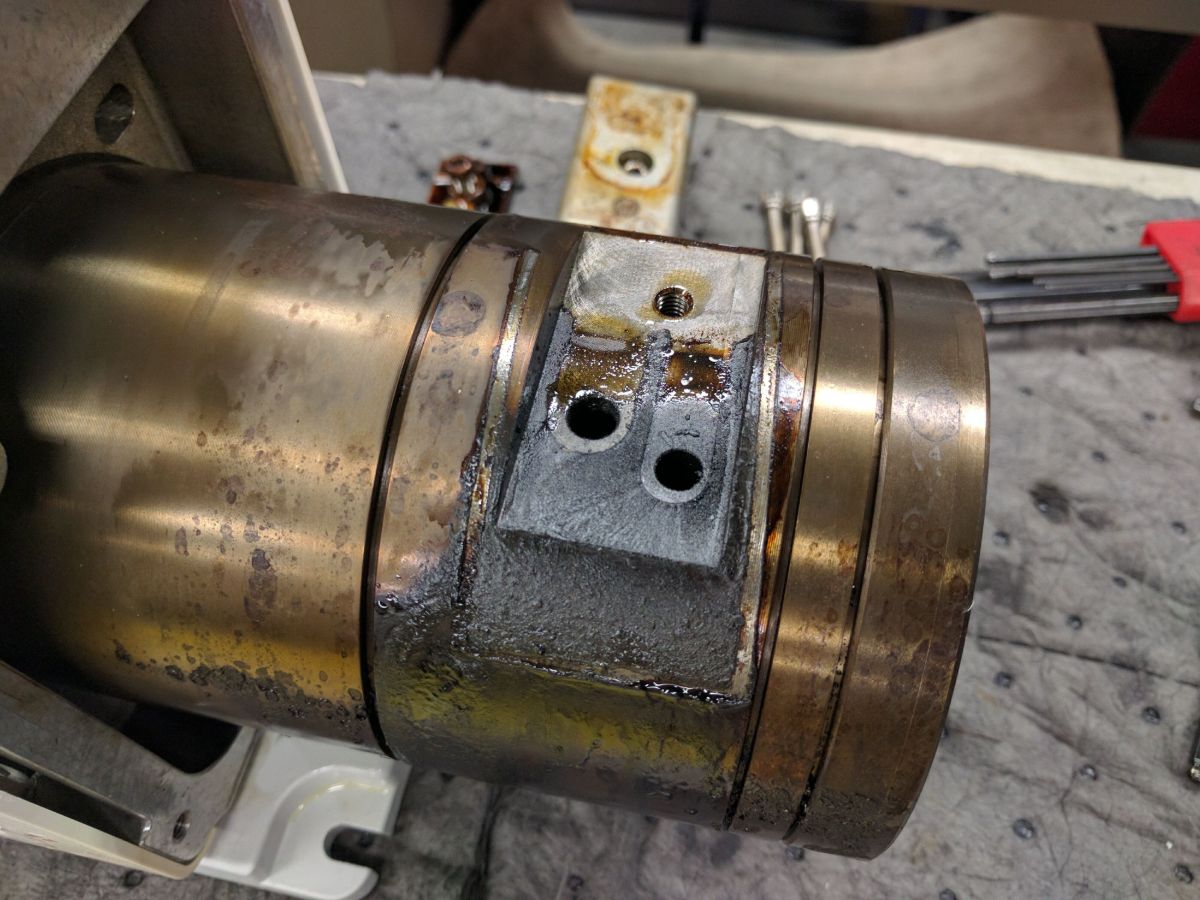

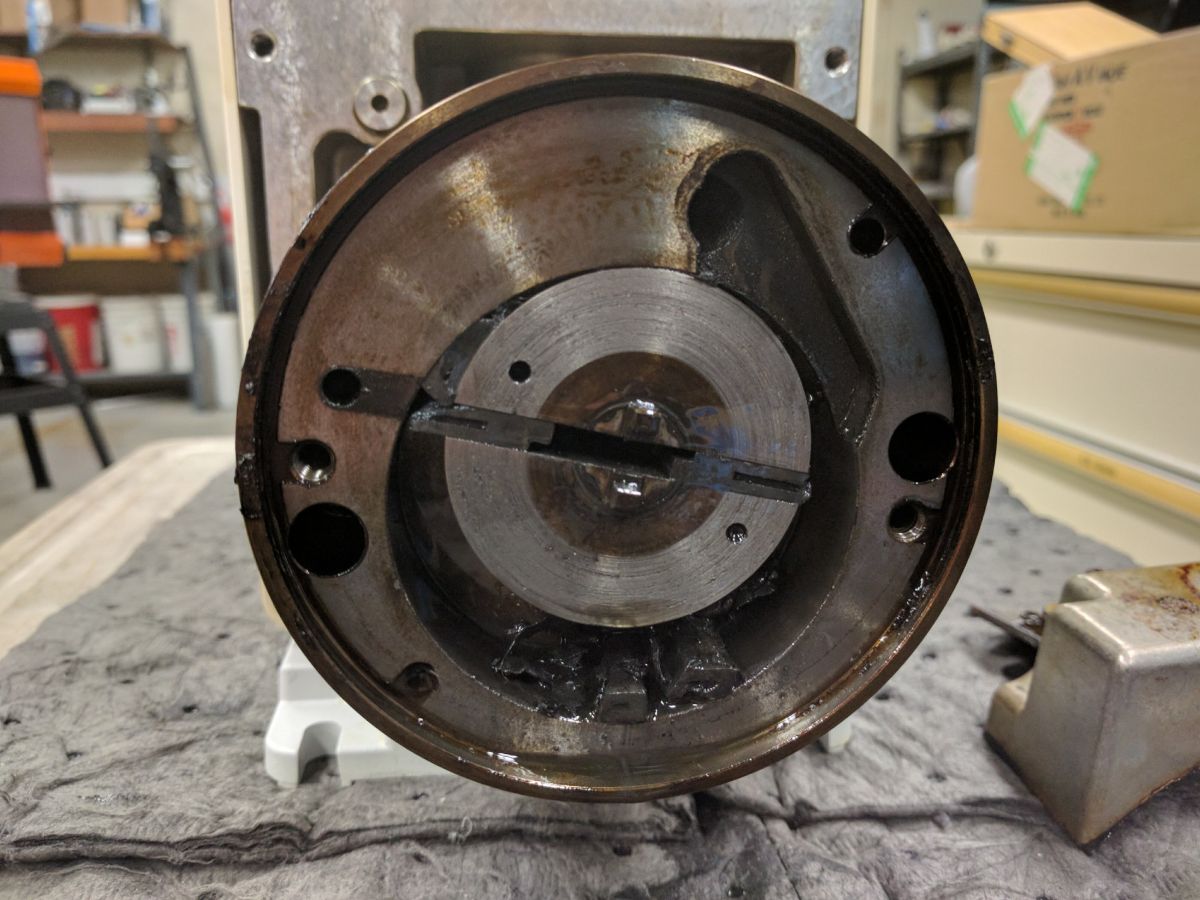

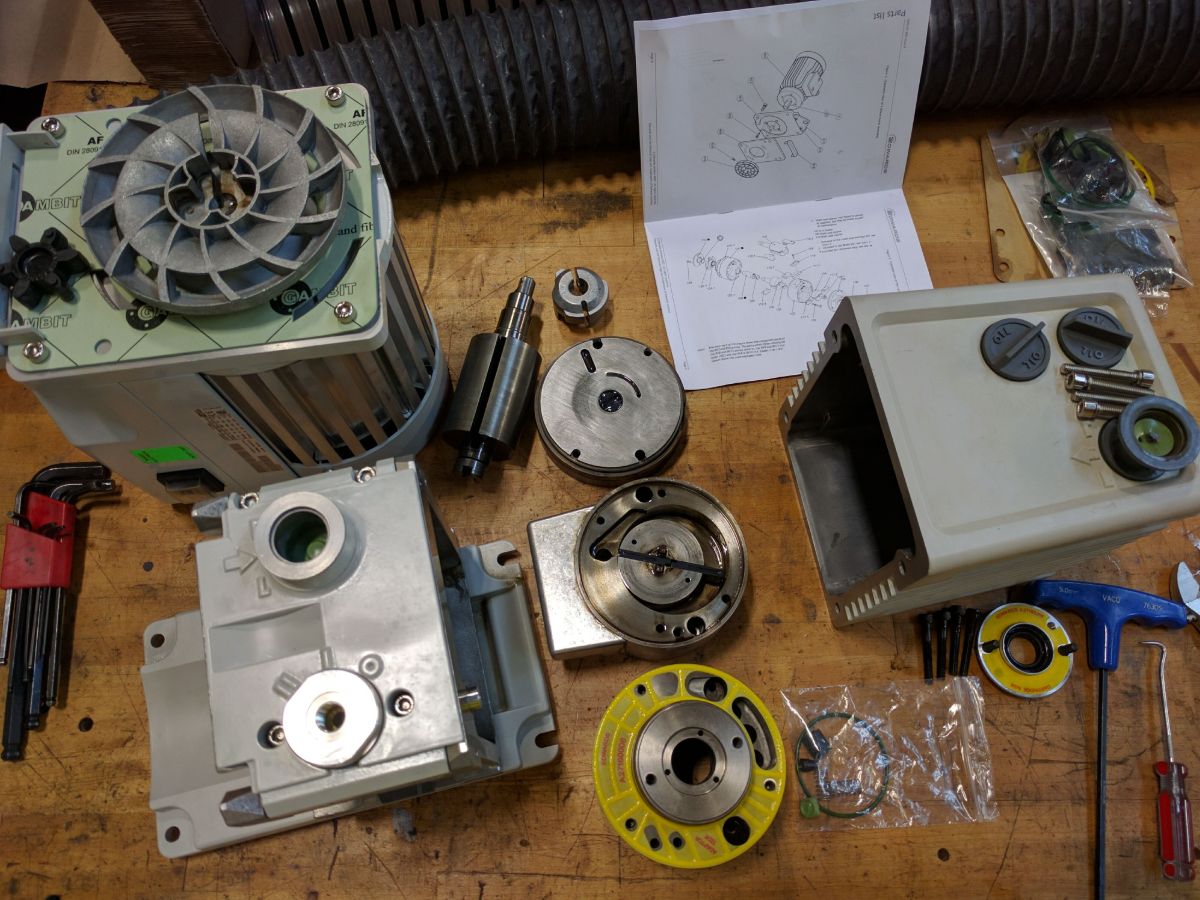

I disassembled the pump, starting by draining the sludge and what was left of the oil. The machine comes apart in distinct pump and motor sections with a coupling in between. Throughout this process, I took lots of photos and referenced the manufacturers parts diagrams that I found online. Inside of the actual pump section, which is a two-stage rotary vane vacuum pump with an oil pump driven off the end of the shaft. The vanes, made out of phenolic resin, had disintegrated, and clogged up the pump and reed valve mechanism causing it seize, as well as contaminated the oil with particles.

Once fully disassembled, I identified the parts that needed to be replaced and sourced a pump rebuild kit that contained all the necessary o-rings, gaskets, springs, and a new set of vanes and valves. I cleaned all of the old parts using solvents and a pneumatic grinder with a Scotch Brite abrasive pad.

I then meticulously reassembled the pump with all the new parts, making sure to apply assembly oil to all the contact surfaces in the pump. When put together, the vane and oil pump assembly was able to be spun by hand before being coupled to the electric motor. When fully reassembled, the oil sump was filled with the correct Welch vacuum pump oil, and the pump was test run for approximately 20 minutes to make sure that it was working properly.

In the end, we managed to repair and continue using the machine instead of simply buying a new one. These vacuum pumps are amazing complex machines, but when working properly, can be run unattended at 100% duty cycle for extended period of time in a crucial lab application.