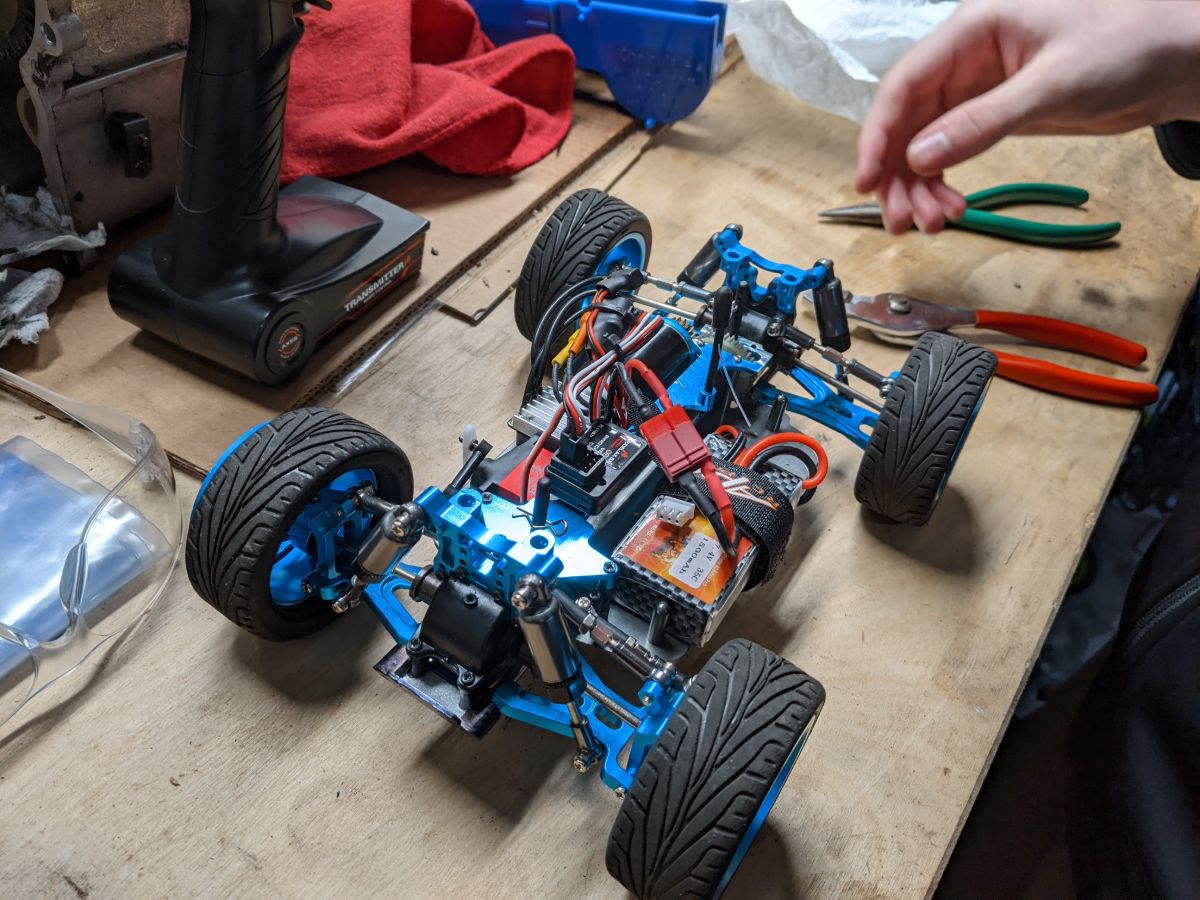

Building an RC Car

When I was looking to get into the RC car hobby, I was researching different RC cars that would allow for the best modifications and parts availability. At the time, one of the best options was the WLtoys A959 RC car available online from the usual online suppliers of cheap hobby supplies.

Pictures

Parts

- WLToys A959 RC car

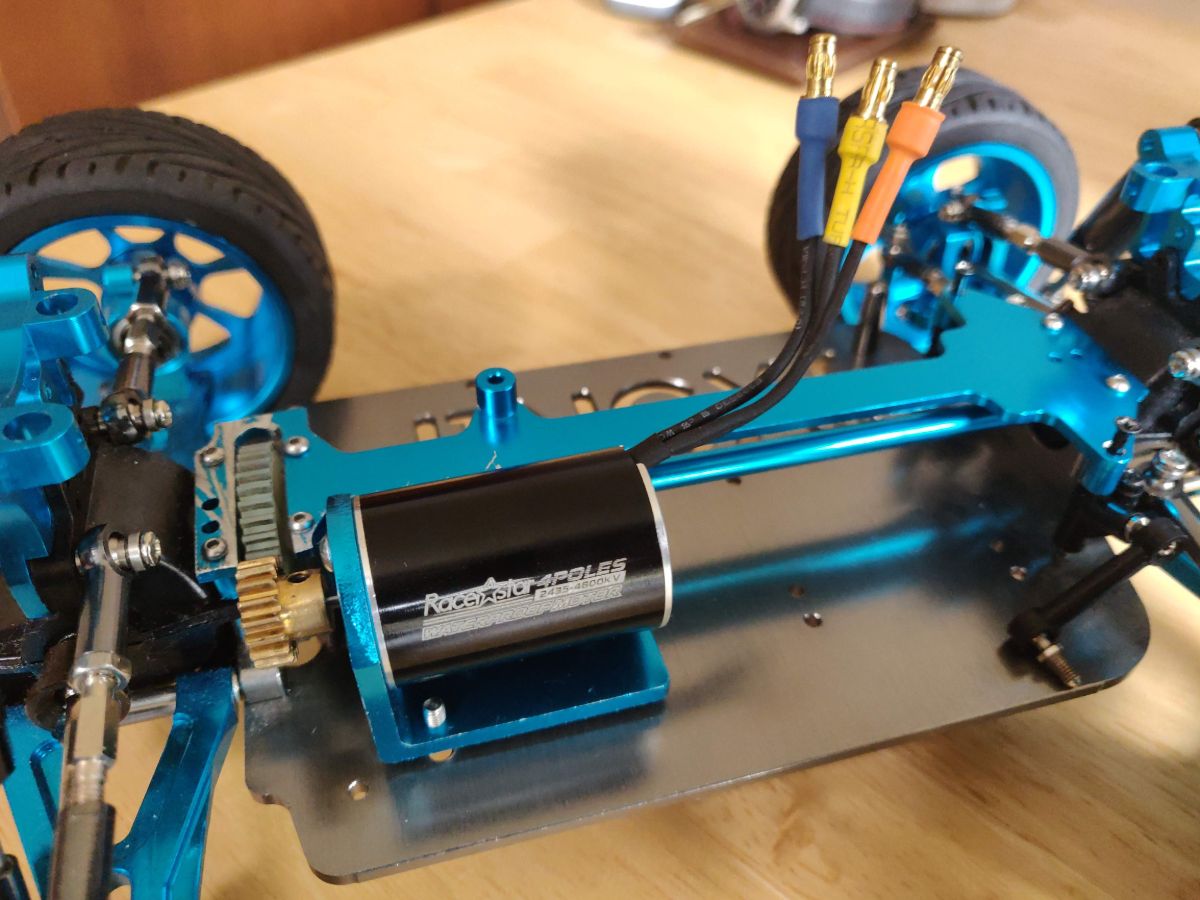

- RacerStar 2435 4800KV Brushless Motor and ESC

- A959 Full Metal Parts Kit

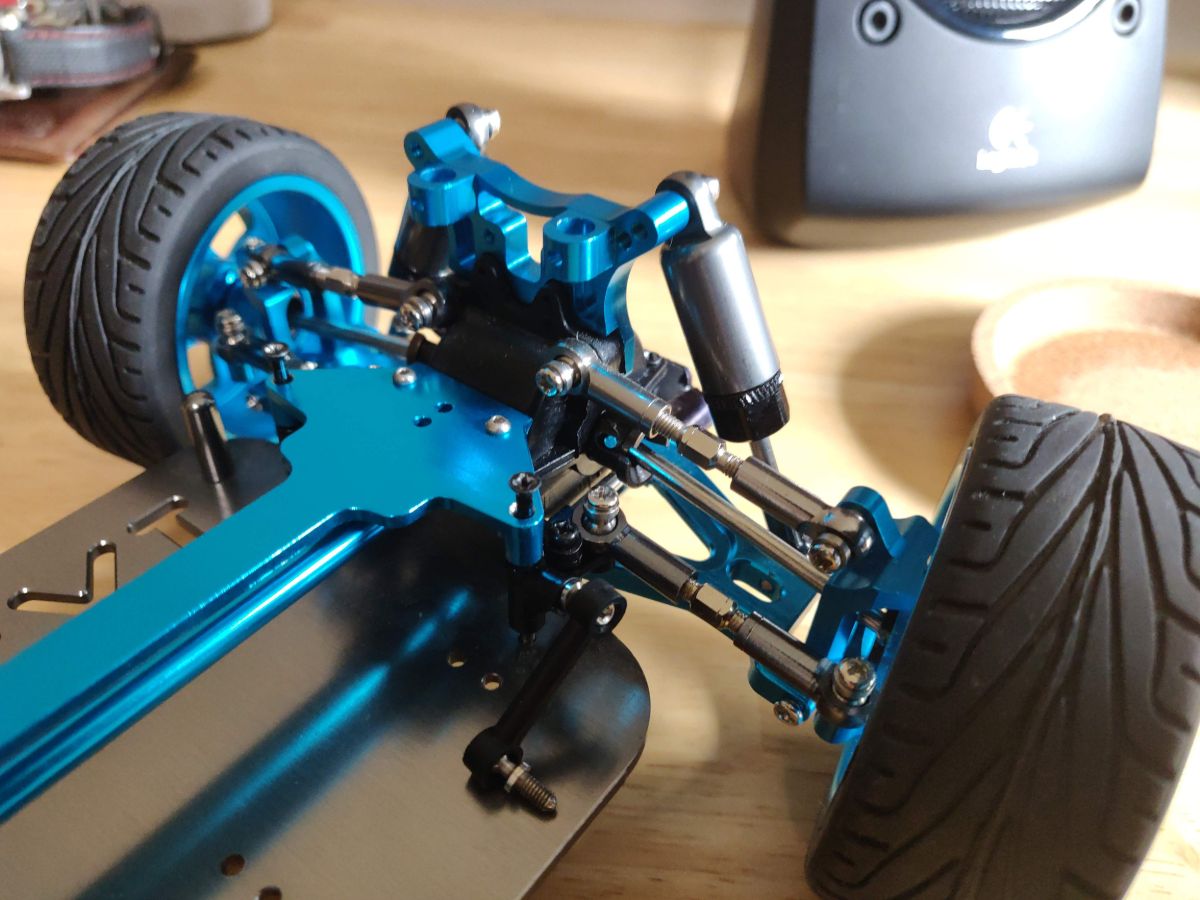

- A959 Adjustable Suspension Linkage Kit

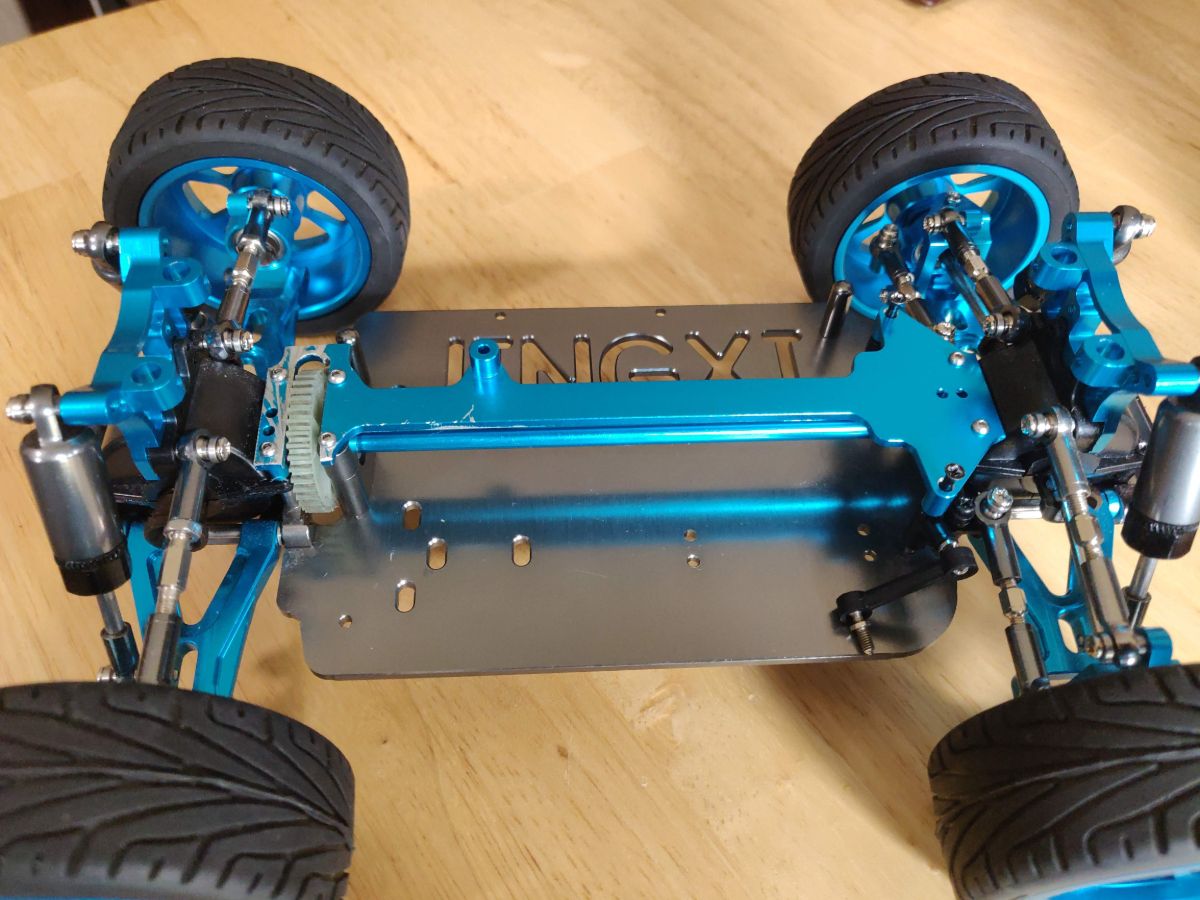

- JingXi A959 Aluminum Chassis/Bellypan

- Micro Metal-geared Steering Servo

- Austar AX-5S 3 Channel Transmitter w/ AX-5X Receiver

- Blue Machined Aluminum Wheels with on-road racing tires set

- 2S 7.4V 1500mAh 35C Lithium Polymer Battery

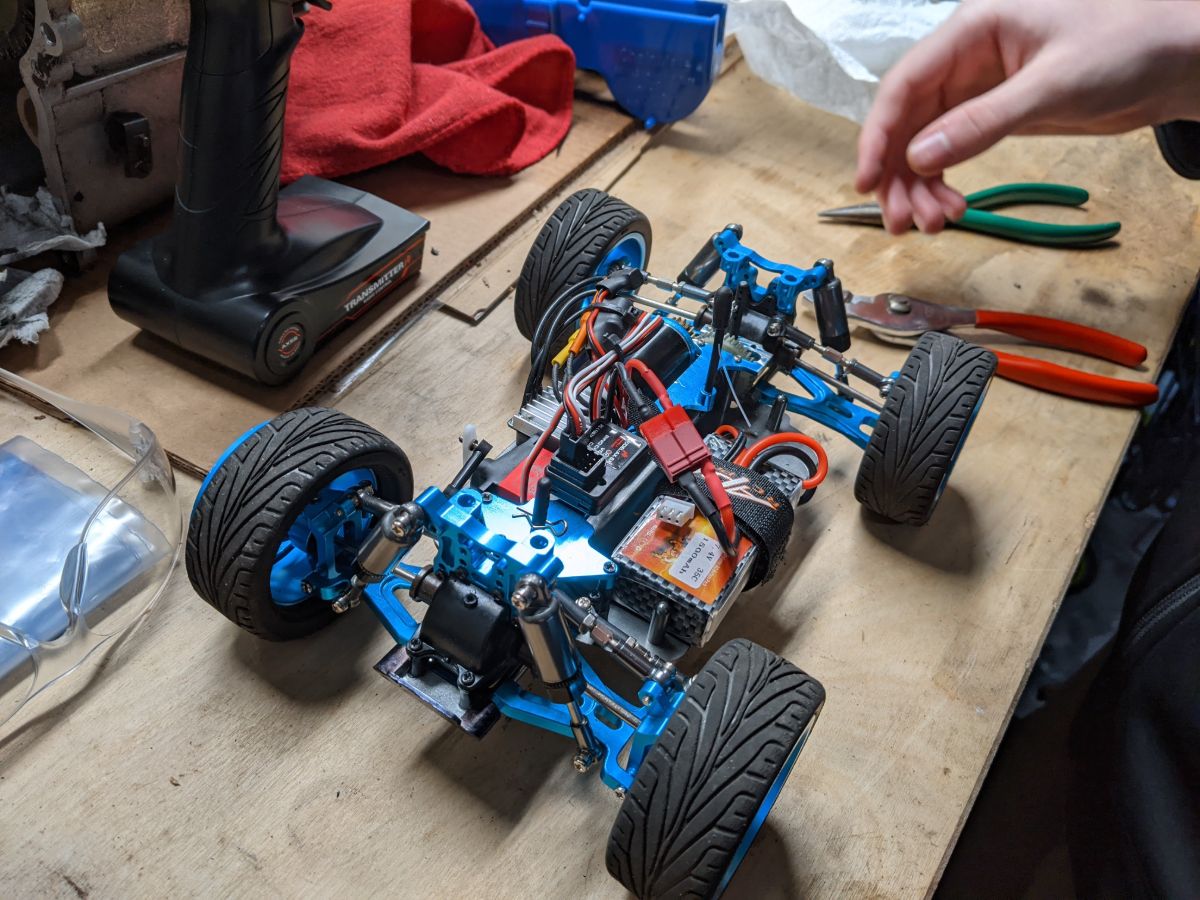

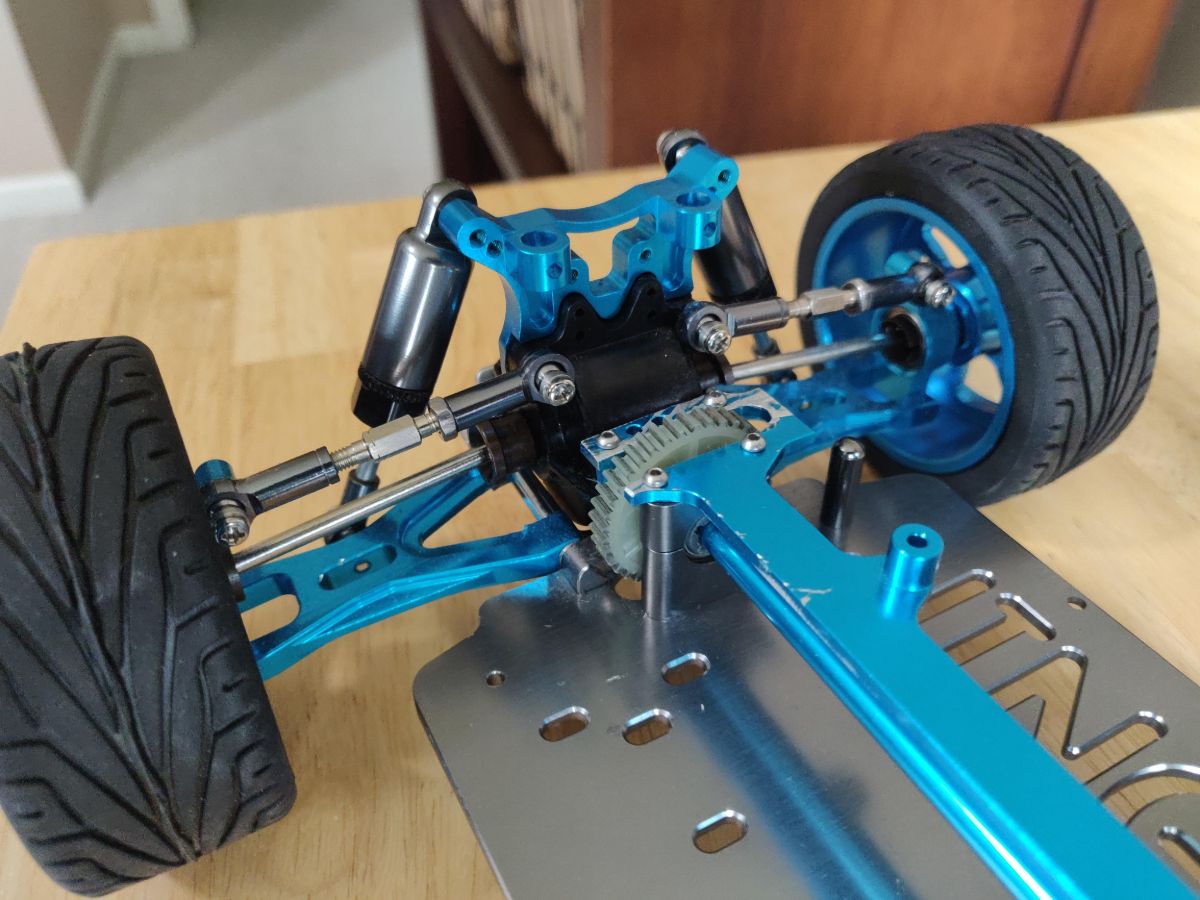

I fully disassembled the WLtoys RC car down to a bare frame and rebuilt it with all aluminum parts and metal gear drivetrain. I installed a new brushless motor and electronic speed controller modified to mount on the existing motor mounts. The steering linkage was the hardest to figure out and get functioning correctly. I ended up installing a generic micro servo motor and drilling holes in the metal chassis where they were missing. I adjusted the suspension linkages and damping characteristics and adding locking nuts and thread locker to prevent things from loosening up over time, as it surely will be driven hard.

For the Future

In hindsight, now that I know a little more about brushless motors, I would need to source a more appropriate motor. That would be one with a lower KV value (spins slower for a given input voltage) because the car is way to fast for it’s own good. I have had to set a throttle limit through the transmitter to keep it under control. In addition, the motor shaft is just slightly to small of a diameter to fit the gear correctly, which results in a drive line vibration and causes the gears to not mesh perfectly, and will certainly lead to more wear on the brass and plastic gear interface.